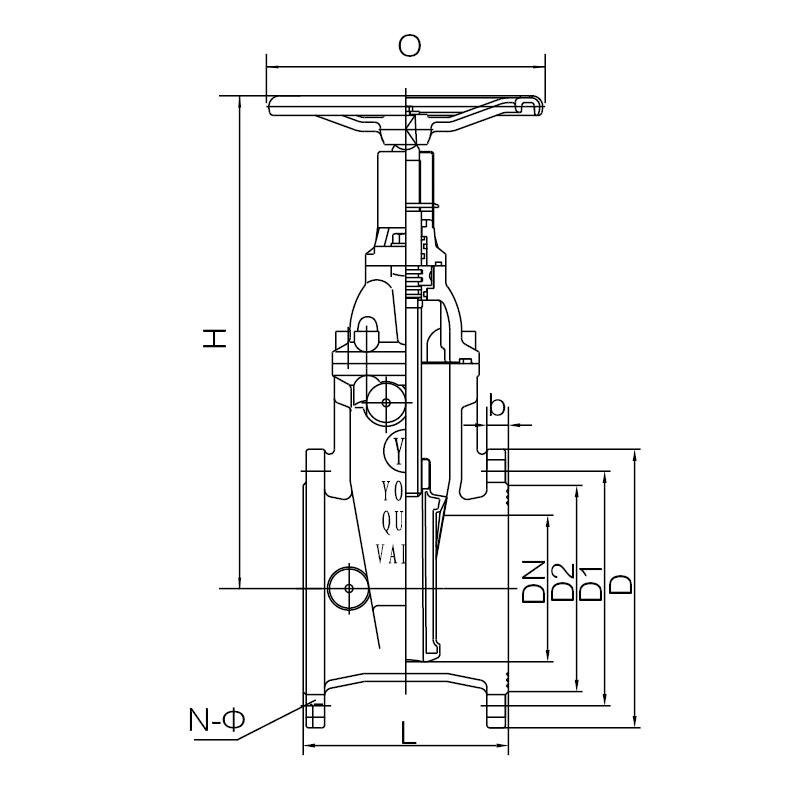

Gate Valve,Flanged,PN16/25

- PN 10/16

-

MaterialDuctile iron

-

Nominal diameterDN40-800

-

Face to face standardASME B16.10, table 1, class 125

-

Flange drillingBS EN 1092 PN10/16, AS2129 TabD/E,ASME B16.1 CL125/150