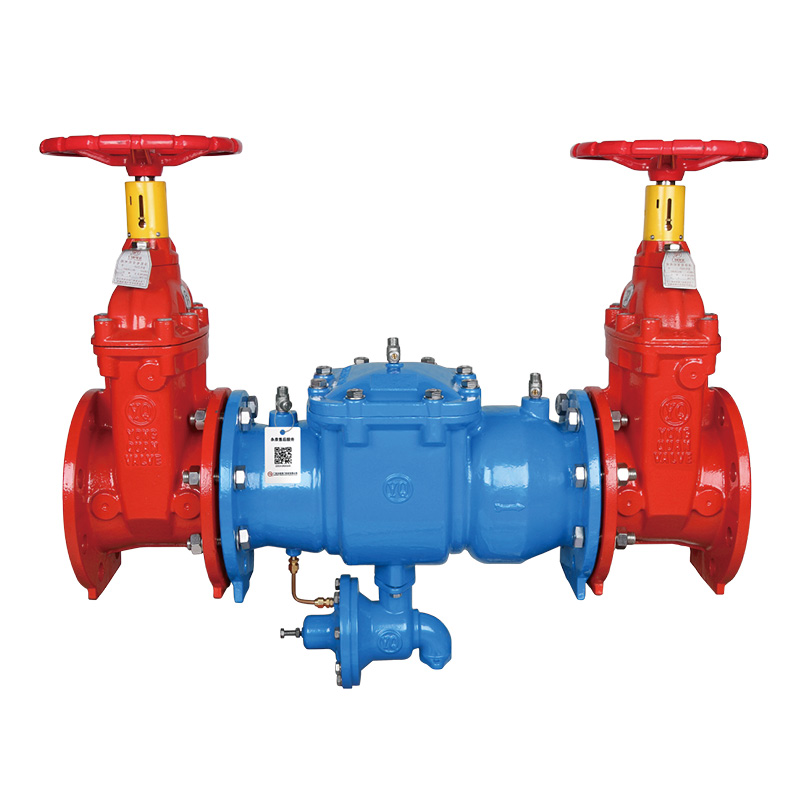

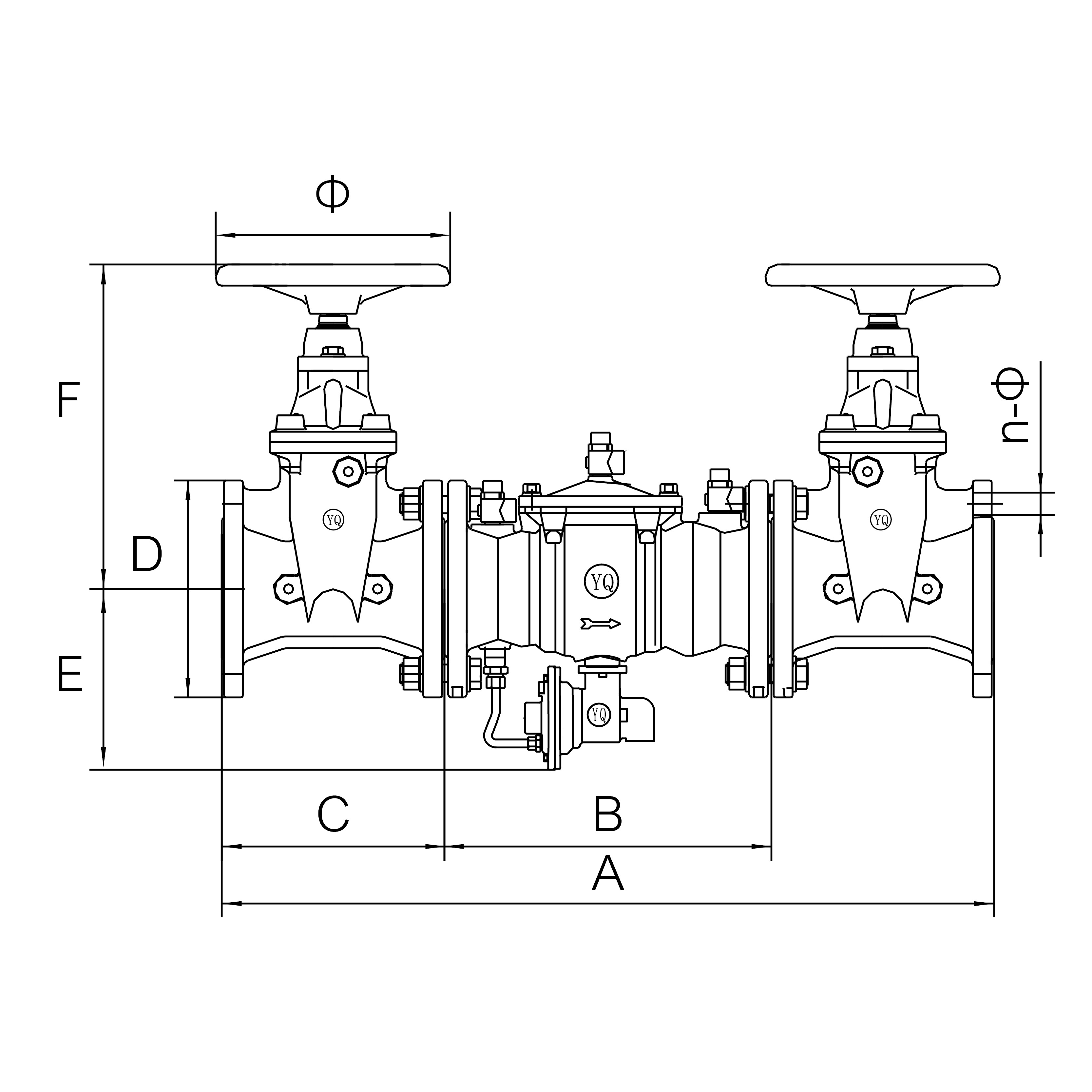

Pressure Reducing Backflow Preventer

- PN 10/16

-

MaterialDuctile iron

-

Nominal diameterDN65-800

-

Face to face standardSeries 3 of BS EN558-1

-

Flange drillingBS EN 1092